R&D in nanotechnology and surface science has led PHASIS to the development of an innovative micro-engraving technology. After a first implementation on the renowned Geneva Hallmark, the technology has now evolved to provide a full digital seal. In partnership with the french OCODE, we offer an innovative digital hallmark that combines high-end surface metallurgy with state-of-the art blockchain and NFT technologies.

The physical and digital seal provides unbeatable authentification features, in particular for track-and-trace of valuable metallic objects (watchmaking, jewellery), but also for the medical industry or safety critical metal parts in general. A secured digital safe, unique for every code, can be used to store information of technical or commercial relevance, or even ‘memories’ of emotional value.

One key feature of the technology is the possibility to write metallic structures on the surface of different alloys. The implemented structures can therefore show very high wear resistance, and also decorative features.

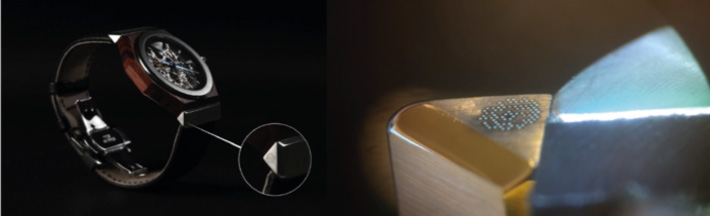

Decorative surface structure, identification code (diameter 2mm) readable by a smartphone.

The digital seal implemented on a timepiece.

The surface quality of the thin films is tested using either atomic force microscopy (AFM) or scanning tunnelling microscopy (STM).

Atomic Force Microscopy

The next tree images are AFM images with lateral size respectively of 1.6 μm x 1.6 μm, 1.1 μm x 1.1 μm and 1.1 μm x 1.1 μm. The z scale is 5 nm for the first image and 3 nm for the last two.

Scanning Tunneling Microscopy

The next image is a 0.5 μm x 0.5 μm STM image of a 2 month old sample kept inside its box. The Z scale is 2 nm.

The size of the terraces may vary from one sample to another. We observe sometime terraces as large as 1 μm2. During the production process, we regularly control the surface quality of our films.

Shelf life

We observe that the quality of the gold surface degrades with time due to some contamination. In order to slow down this process, we package the gold thin films in pure nitrogen immediately after the deposition process. This procedure allows the extension of the shelf life of the product to three to four months. All our films are freshly grown, we keep no stock of this product and we strongly recommend the use of the films in a short time scale after reception.

Epitaxial Au(111) thin films are grown in controlled high vacuum deposition systems using a magnetron sputtering technique. Details on the deposition technique can be found here. The gold source target is made of pure gold 99.99%. The films are grown at high temperature in a controlled argon atmosphere.

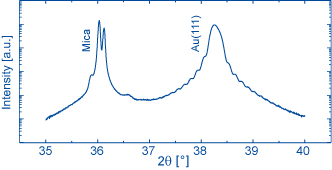

Epitaxial growth of thin films refers to extended single-crystal film formation on top of a crystalline substrate. The structural crystalline quality of the films is checked by X-ray-diffraction analysis. The next figure shows an example of a θ-2θ X-ray analysis performed on a typical 70nm thick gold film.

The analysis shows a pure (111) growth with a c-axis lattice parameter of 2.36 Å. Moreover, the finite number of diffracting planes leads to oscillations of diffracted intensities whose period is related to the layer thickness. The occurrence of these oscillations around the (111) reflection indicates a high degree of crystallinity of the samples and allows us to precisely control the thickness of the films.

Substrates

Phasis gold thin films are grown on high grade muscovite mica sheets freshly cleaved. The quality of the mica is classified from V-1 to V-10 according to the ASTM international standard. V-1 is considered as the best quality. It is a visual system of classifying the quality of natural muscovite mica based upon relative amounts of visible foreign inclusion. At Phasis we are using muscovite mica with quality higher of equal to V-2. The mica sheets are cleaved just before their introduction into the deposition system. The thickness of the final cleaved mica sheets may vary from 0.080mm to 0.130mm. The mica cleaving process is of random nature and the final thickness of the mica sheets cannot be controlled with better accuracy.

Gold size and thickness

Phasis offers the gold films in various geometries and sizes. The largest gold deposited region is 2 cm x 2 cm and the smallest 4 mm x 4 mm.

Cutting a gold thin film grown on mica into smaller parts degrades the gold surface. Mica is indeed a very hard material and thus difficult to cut. With the different proposed geometries, the cutting process becomes easier because it can be done in-between the gold areas without damaging the gold surface. It is thus possible to maximise the number of possible measurements. Do not hesitate to contact us if you have a request for a special gold geometry not proposed in our list.

The typical gold thickness we provide is 200 nm. With our experience, we know that 200 nm thick films present good surface quality. We can grow thinner of thicker films upon request. For very thin film however, the gold surface will present islands with holes in-between, the film being not thick enough to allow a better covering.